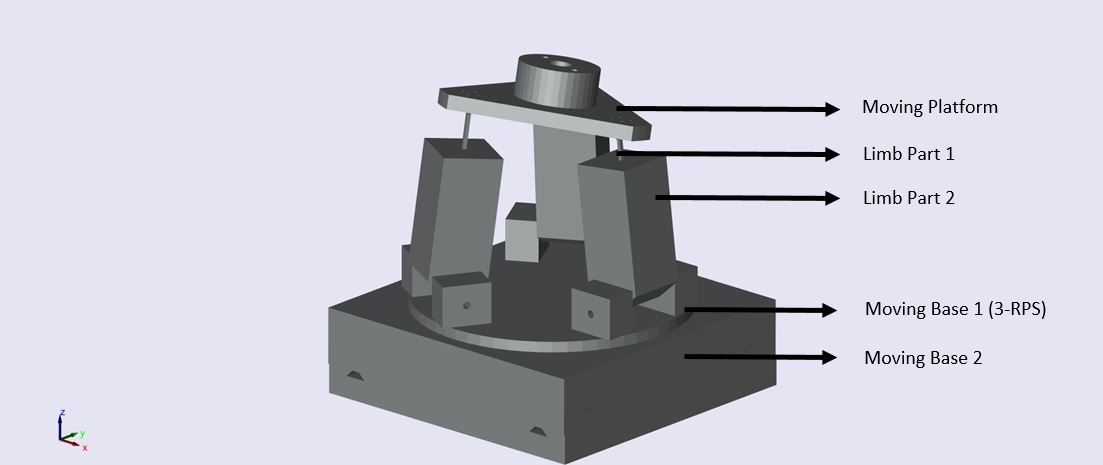

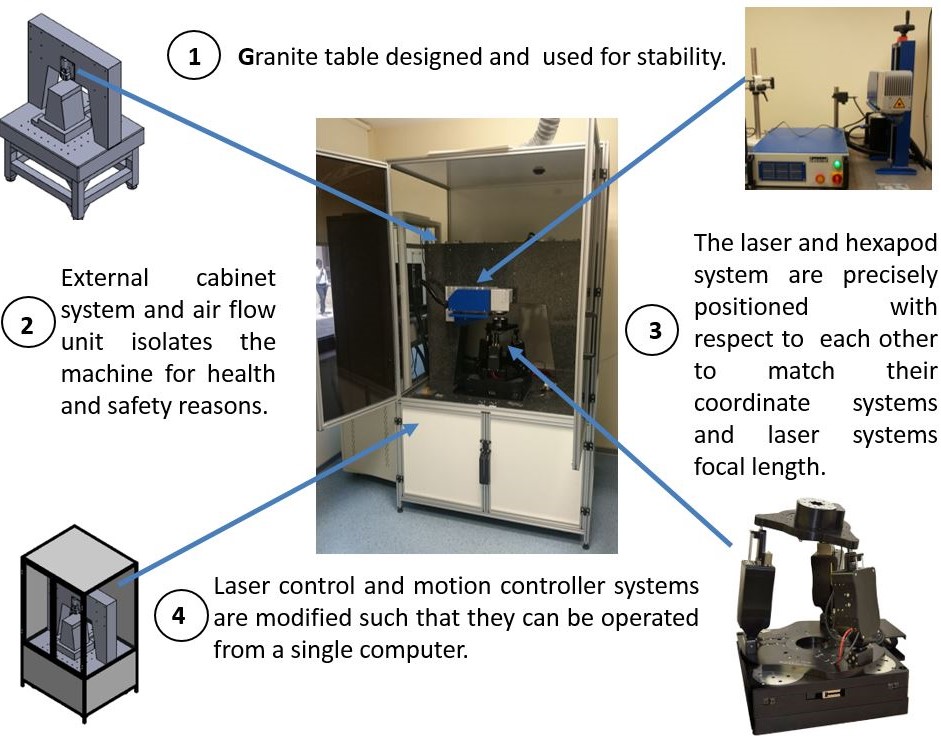

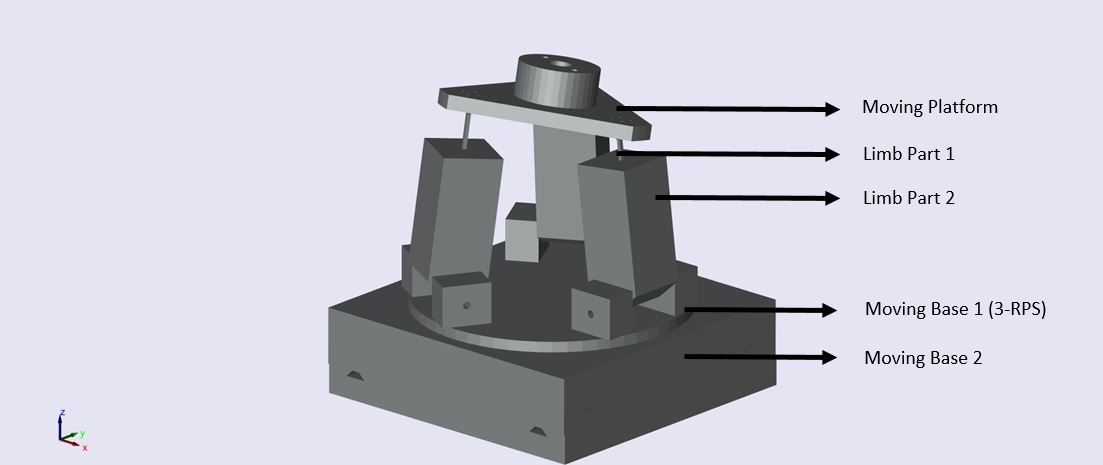

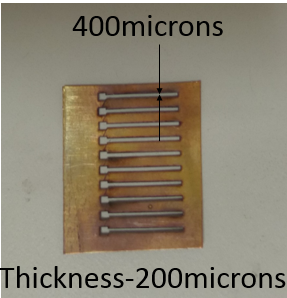

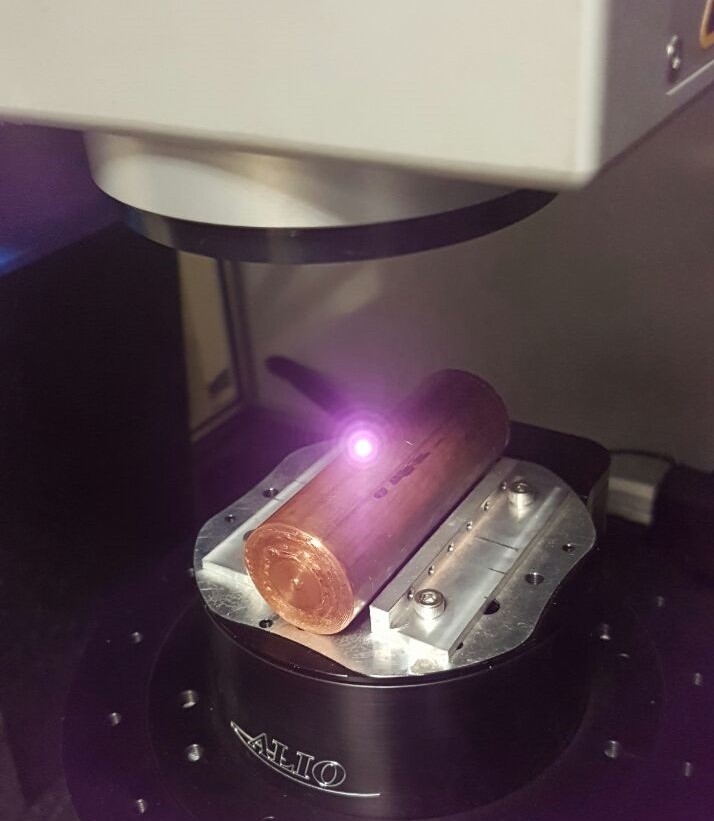

In this work design and development of a micromachining system that can perform on non-linear contoured surfaces is studied using a parallel manipulator system. The laser micromachining system is designed and assembled, including a nanosecond Q-switched pulsed fiber laser, a 6-DOF hexapod manipulator, a granite table to absorb vibrations, and an external cabin system to isolate the whole system for safety and health issues. Performance characteristics of micromachining devices are mainly determined by the precision and characteristics of each individual component of the system. Very complex shapes can be scanned in various ways using the extra degree of freedom in the system.

The main motivation for this research is the improved surface quality in already manufactured parts. In many cases, the shape and the feature of the finished product require an additional degree of freedom to be scanned with a laser system.