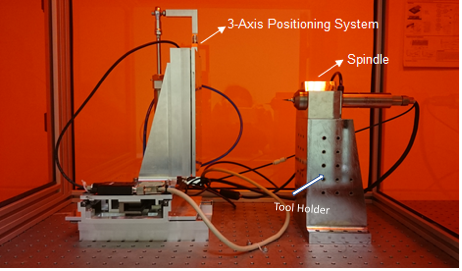

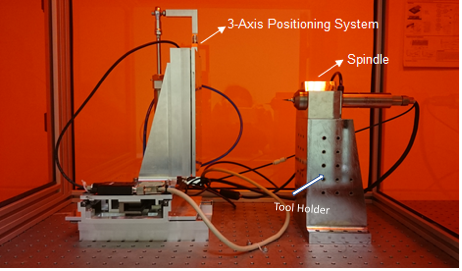

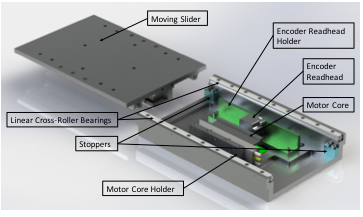

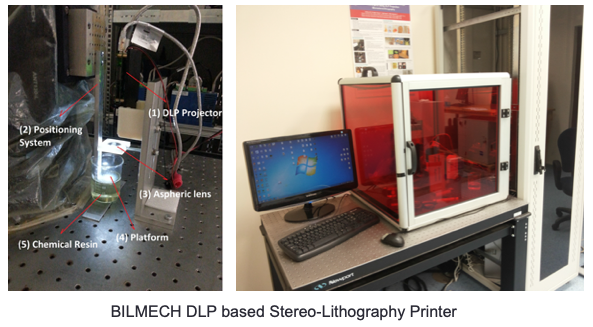

After completing the modular multi-axis nano-positioning system discussed above, a Multi-Axis Manufacturing System was built. The manufacturing system can rapidly transform between milling, rapid prototyping, and laser cutting configurations. The presence of these new configurations introduced constraints in the design with different disturbance characteristics. The robustness (micro-milling), repeatability (laser cutting), and smooth tracking (additive manufacturing) of the positioning systems were studied using the same framework of the controller from before.

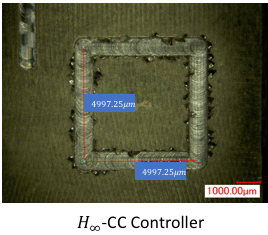

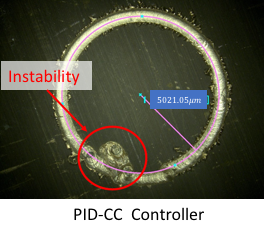

A three-dimensional robust controller was developed for the positioning system using a novel identification method for each axis. This is especially important for micro-milling, where the dynamic interaction among components is significant during cutting. Additive Manufacturing using stereolithography is an expensive and long process. It requires various calibration activities based on the shape of the product. Using mathematical modeling and iterative learning, the dimensional accuracy of the products can be improved by adjusting the device’s reference input (z-axis velocity). The robust controller with the cross-coupled controller was introduced and tested.