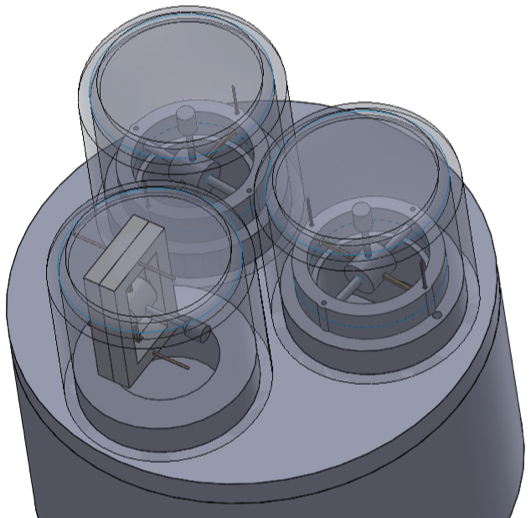

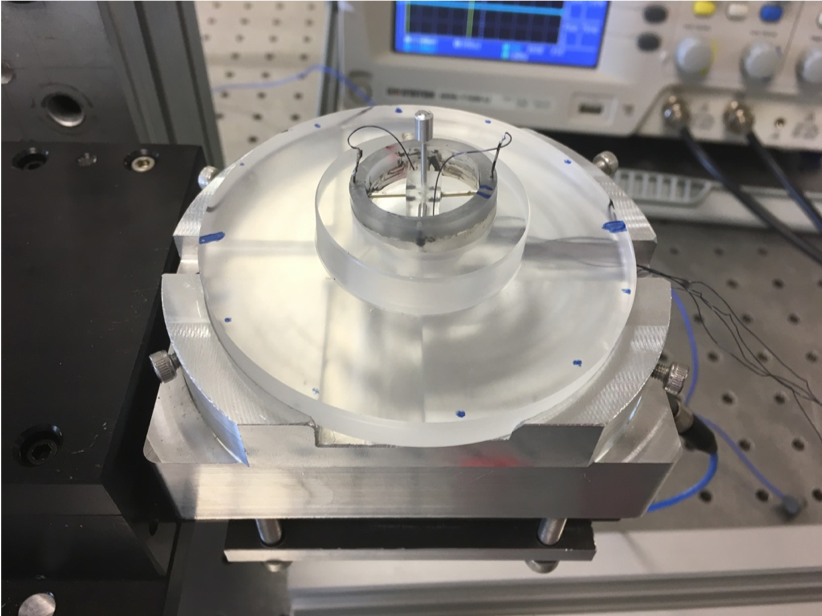

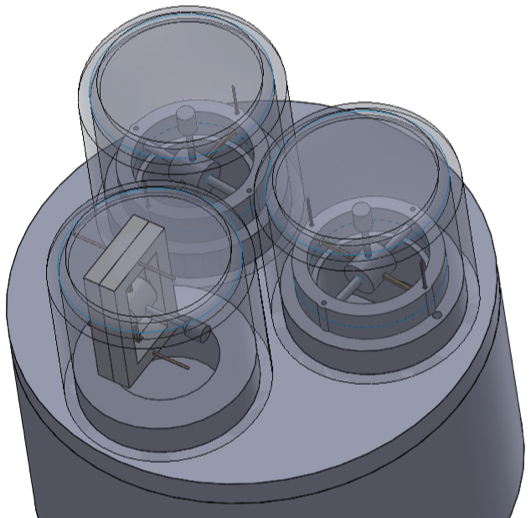

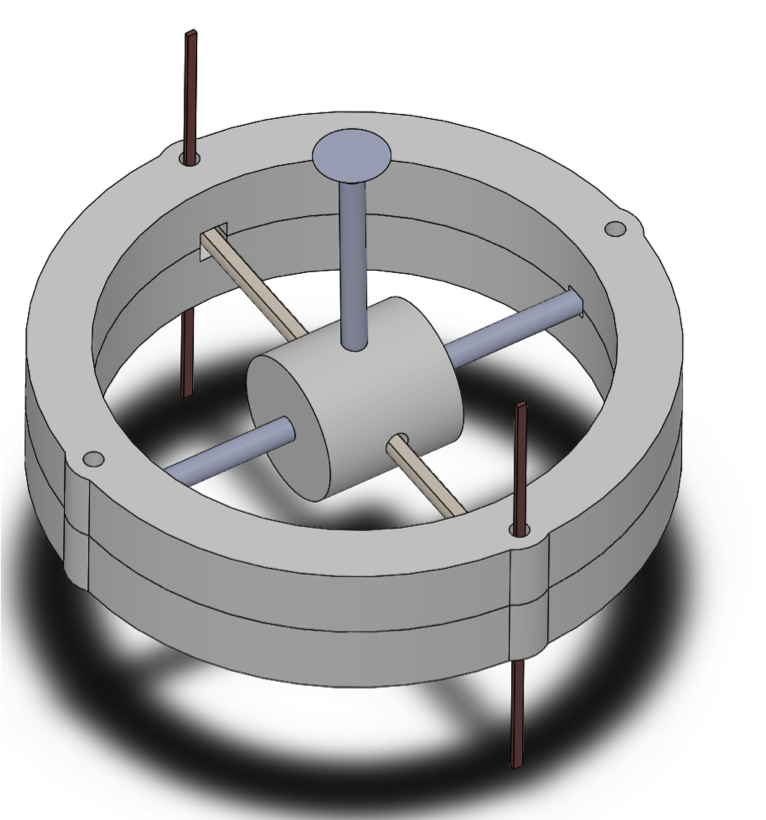

An Acoustic Vector Sensor (AVS) is a device used to detect acoustic signals by converting the mechanical energy of an incident wave to a detectable electrical energy using the acoustic particle principle from the literature. Its design is based on two parallel piezoelectric beams attached to a mechanical sensing tip using a rotary joint component. The sensor uses piezoelectric elements to convert mechanical strain into sensible electrical signals. The design of the sensor is modular; that is, individual modules can be easily maintained, tested, and calibrated. All sensor parts have been fabricated by mechanical micro-machining and precisely assembled using representative tests on individual pieces and dynamic simulations in the assembled sensor system. Complete design, analysis, and vibrational testing of an acoustical sensor were performed. The results of this project can be used to build a sensor for a manufacturing system. The developed sensor is proven to have a very good SNR ratio at a wide range of frequencies. It can detect vibration and accurate displacement measurement systems if packaged as a smart sensor in manufacturing systems.