In manufacturing systems, axis controllers’ modular design causes performance loss due to the system’s coupled nature, although it increases systems’ maintainability and upgradability. This coupled nature of the system can be addressed by building controllers that consider the effects from the other degree of motion of the system. Modularity is adversely affected when multi-input multi-output control systems are designed due to the increased interaction of axis controllers.

In this research, an axis-based modular cross-coupled controller using iterative learning is designed with adjustable performance metrics. The resulting system’s stability is proven with the new controller.

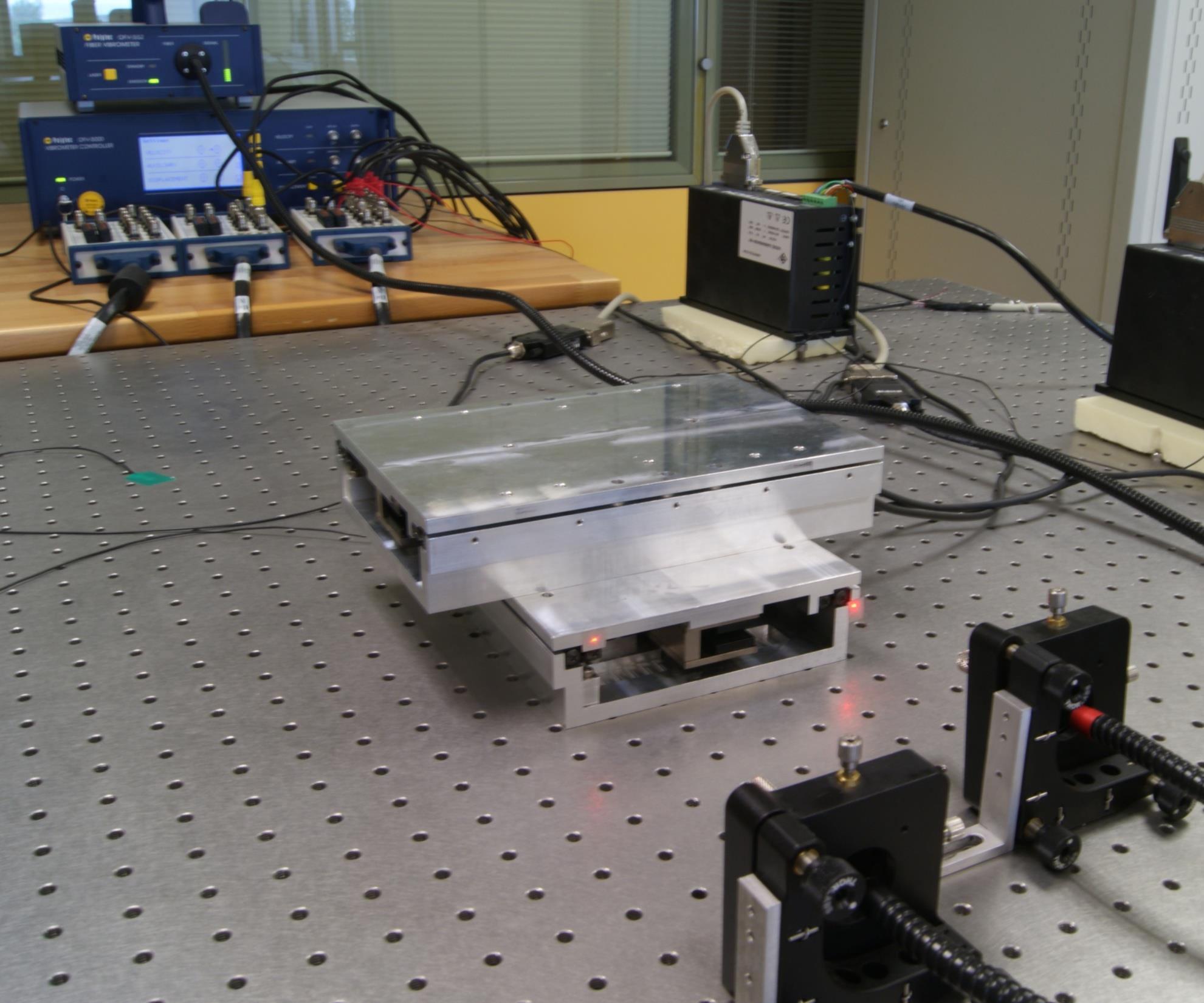

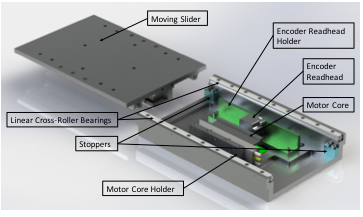

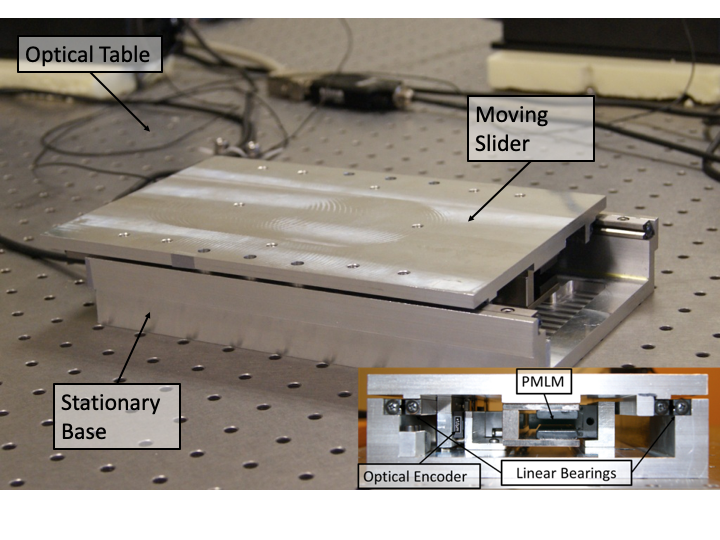

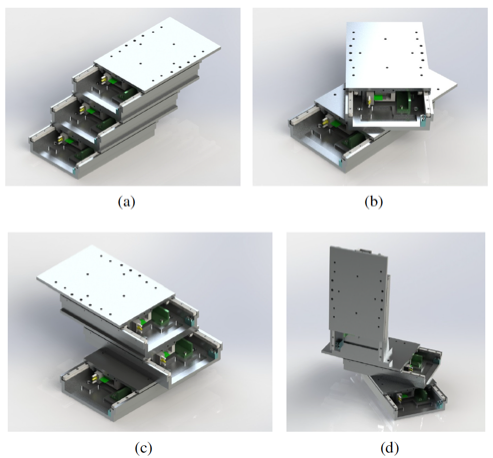

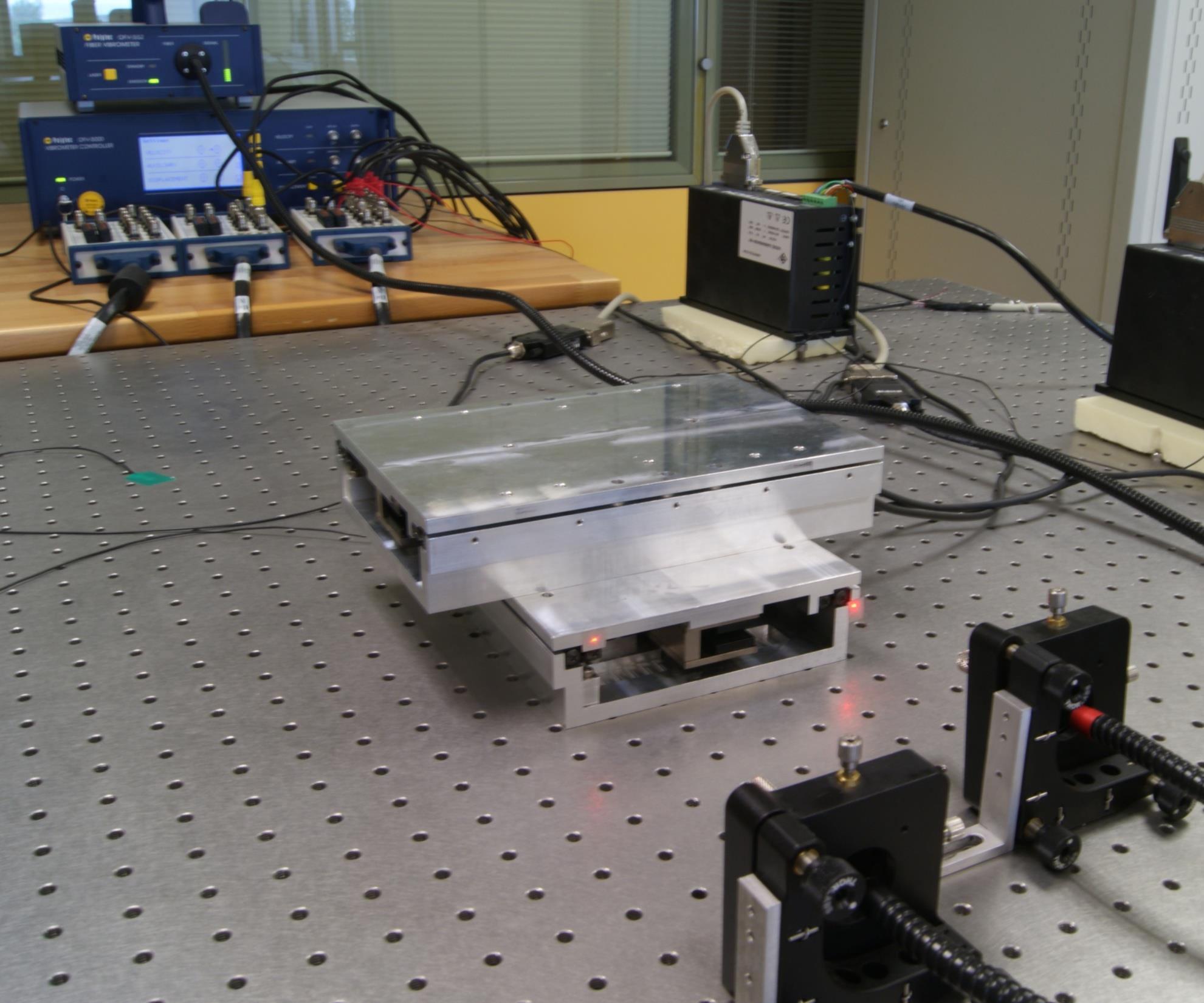

The theoretical results were then applied to a three-axis nanopositioning system designed and built by the SMechS group. The proposed controller also features an adaptive quadrature interpolation algorithm that reduces the resolution of a 1-micrometer optical sensor down to approximately 30 nanometers using a novel interpolation method. Adaptation fortifies the sensor reading against electrical noise. The structure proposed in this controller is modular. This helps us increase and decrease the number of axis (or motion directions) to control without changing the rest of the system’s design. The iterative learning structure and contour vectoring approach are combined so that the mechatronic modularity and the stability of the resulting system are guaranteed. Moreover, by embedding ”smarts” in the sensor, the adaptive interpolation technique made it possible to build a much less expensive system without compromising the resolution performance.